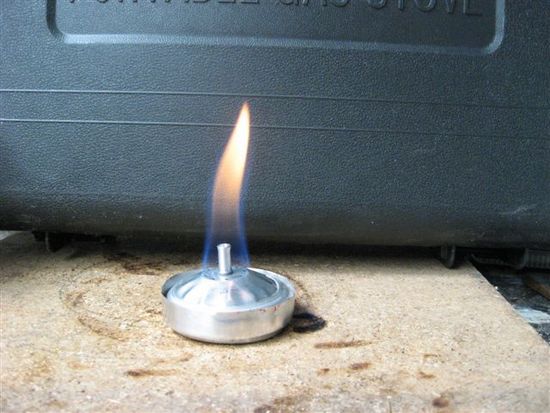

I invite you to take a look at: DIY Alcohol Stoves -- Basic Design Considerations.

HJ

Hi, Tony,Tony wrote:Hi HJ,

Many thanks for posting this information, it is very interesting that a height to burner hole diameter is a around a 1:1 ratio, when I checked my Trangia burned it has height of 41.75 mm and a hole diameter of 39.9 mm, though the 12-10 is a little off the 1:1 ratio, it has a 35mm height and 30 mm hole diameter.

Have you thought about the influence of mass on alcohol stove performance, I often think this is overlooked in alcohol stove design, with my volcano stove design I can adjust burn times with changing the mass of the center pin.

Another consideration is the temperature of the ground or in stove testers case the temperature of the test bench, I have noticed that when testing and using the same place on the bench or ground the efficiency can change as the bench or ground warms up, I use several pieces of wooden board that I exchange between tests.

When I do my testing I start with what ever temperature the water comes out of my tap I use 500 ml (500 grams), I then run the test but I monitor the temperature and when it gets to 95ºC I then terminate the test, I then calculate the fuel used per ºC, I then I times this figure by 80 to get a result of grams of fuel used/80ºC in this way I can accurately compare results.

Tony

I was hoping you might weigh in on this issue since you know more about stoves in technical terms than I will probably ever know (unless you or someone like Roger teach me).

First, let me say that most of my testing is done out in the field and done without the benefit of any precise measuring equipment. I do of course have a measuring cup for the water and another for the fuel, but I have no temperature probes, gram scales, or the like. So, when I say "about," what I mean is that I can see that there is a relationship between, in this case, height and burner opening size, and I can see that it approaches 1:1 for a practical stove, but I cannot precisely determine the ratio. And of course "practical" will mean different things to different people.

Second, these results are (necessarily) very narrow in scope. I would have a write up longer than the the voter registry of China if I were try to cover all aspects of alcohol stoves

I have not experimented with the effect of the mass of the materials of a stove and the effect of that mass on burn characteristics

I absolutely have noticed the profound effect that ground temperature can have on burn characteristics. I believe I've done enough testing under enough varied conditions that I've got reliable results. I have also compared notes with other homemade stove builders. My results compare well with theirs. I will however continue to tinker.

hikin_jim wrote:I absolutely have noticed the profound effect that ground temperature can have on burn characteristics.

I started getting interested in alcohol stoves in the summer of 2007. At that time, I didn't have the foggiest clue of what might constitute a good design vs. a poor one. I read a lot on BPL. I purchased some stoves and made others. Things really accelerated in 2010 when I found out just how inefficient the stove I was using was compared to the stove of a good friend of mine. I actually ran out of alcohol on one particular trip and couldn't finish my cooking. I got really disgusted and decided to find out about alcohol stoves. Now, I have a pretty good, intuitive idea of what will make for a good stove. Plus I can bounce things off of people on forums such as this.Orion wrote:I'm curious, all the "tinkering and testing", is it more or less a trial and error method to figure out what works? Or do you have a sense for why some designs are better than others?

Tony will have more to say about this I'm sure, but my read on the matter is that it's probably more than just the mass. I would think that it has to do with thermal conductivity, surface area, and mass. Again, I will defer to Tony who has greater scientific background and has done actual testing, but, just based on what I've seen of the stove, I'll make some general remarks.Orion wrote:For example, why would the pin mass on Tony's stove matter?

In my opinion, the Trangia is a very good burner overall. I think it's a nice balance between speed and efficiency. It's robust. The simmer ring gives one the ability to a) simmer and b) easily extinguish the stove. The cap with it's "O" ring seal allows one to leave unburnt fuel in the stove for later use. Other than perhaps the weight, I have nothing but good things to say about the Trangia burner.Orion wrote:Also, ignoring weight, is the Trangia considered a really good burner or just an okay one?

Tony will have more to say about this I'm sure, but my read on the matter is that it's probably more than just the mass. I would think that it has to do with thermal conductivity, surface area, and mass. Again, I will defer to Tony who has greater scientific background and has done actual testing, but, just based on what I've seen of the stove, I'll make some general remarks.

Since the central pin in Tony's volcano stove is in direct contact with the body of the stove, heat will naturally be conducted into the stove body. The mass of the body will absorb some of the heat, and then transfer that heat into the fuel which in turn will cause increased vaporization in the fuel which will affect the overall rate of combustion. If the central pin were stainless steel (a relatively poor heat conductor), I would expect less thermal conduction. If the central pin were copper (a relatively good heat conductor), I would expect more thermal conduction. Greater mass in the pin would generally transfer a greater amount of heat although there may be a limit over a certain amount of thickness. If the pin's mass were arranged in such a way to maximize surface area, I would expect greater heat transfer. Those are just some general remarks. I'm sure Tony can give us some very specific empirically derived data.

Tony,Tony wrote:When I do my testing I start with what ever temperature the water comes out of my tap I use 500 ml (500 grams), I then run the test but I monitor the temperature and when it gets to 95ºC I then terminate the test, I then calculate the fuel used per ºC, I then I times this figure by 80 to get a result of grams of fuel used/80ºC in this way I can accurately compare results.

Tony wrote:I cannot remember the results with the copper pin but I think it did not work as well as the aluminum pin I am using at the moment, in all cases the stove body also heated up which I think is from the flame not from any feed back from the pin, the contact area is very small. I will have to go through my stove results note book to find my test data.

Quite understandable. You wouldn't hear from me for a week.Tony wrote:I have been reading your post with interests, sorry about not replying to some of your posts but I have been busy at work trying to get some experiments up and running, I am hoping things quiet down soon and at home I have been distracted by being given a very good book about Mawson, Shackleton, Scott and Amundsen I am enjoying the book so much I am struggling to put down.

Generally, yes. If the flames go up the side of the pot, fuel is being wasted. It's better to find a stove that burns a little bit more slowly with a bit smaller flame. The ideal is a flame that stops a cm or two short of the edge of the pot.andrewa wrote:...the side burners certainly worked, but the flame shot out well beyond the cutlery stand and the billy, which seemed wasted heat, even with the windshield to direct it up the sides of the pot.

That's what makes comparisons different -- there are so many variables. Windscreens and stands like yours can dramatically change the burn characteristics. In your case, I'd say the windscreen/pot support set up reflected a lot of heat back to the burner which caused the fuel to vaporize more rapidly which in turn caused your stove to burn hotter.andrewa wrote:With the coke can stove in my "Ikea stove stand", I was surprised that instead of getting the rather weak 2-3cm vertical jets out of the holes around the rim which you get when resting the pot on a wire stand, something happened whereby the jets became more powerful, and started to shoot out sidewards, beyond the confines of the Ikea stand...

Not bad on fuel consumption, and you got a pretty good duration for 20ml. The more efficient stoves out there boil 500ml with 15ml metho. At least that's the standard I aim for. Relatively few stoves can beat that, and those that do are typically very "touchy" and take forever to bring water to a boil.andrewa wrote:20mls of metho boiled 500mls of tap water in 10-11 mins, and burned for ~12mins

michael_p wrote:Thanks for the thread hikin_jim, another good read.

Ah, yes, I believe I can relate to that. Got any photos for us?Ticklebelly wrote: Interest only, really, I love the tinkering.

Users browsing this forum: No registered users and 5 guests