I found that the hot cutter could quickly weld two or three pieces of fabric together while cutting, so that for example, a long tent seam could be quickly prepared for easy sewing of Mock Felled Seams, which some of us 'crap sewers' would otherwise find difficult.

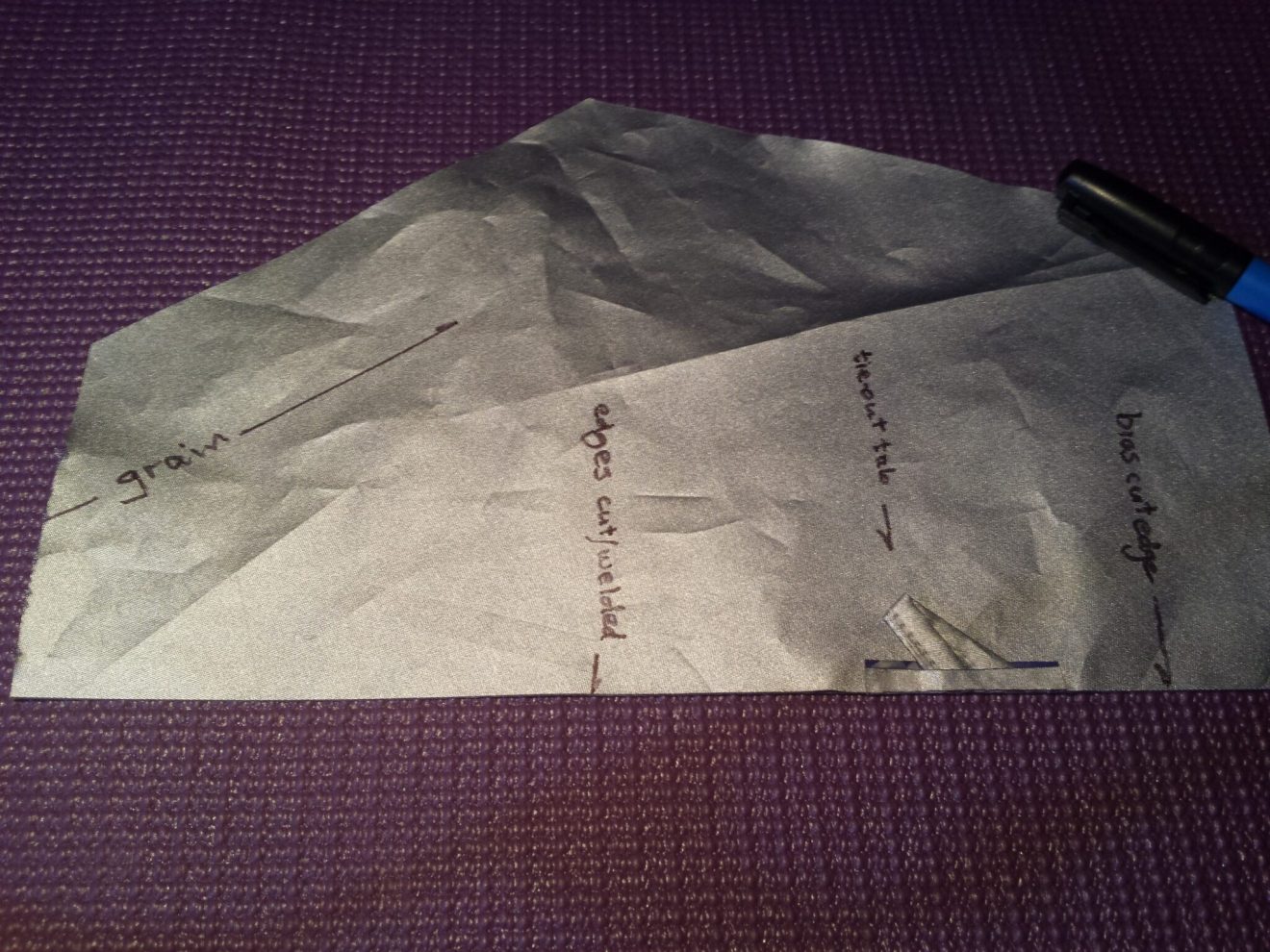

I also found that tie out tabs for the tent could be welded in place, at the same time. This meant that they were ready to be embedded in the tent seams as the two rows of stitching were made without the need to remove the work from the sewing machine. This makes the otherwise difficult sewing of bias grain fabric to straight grain fabric easy as shown in the photos of a sample seam that is started with hot cutting welding below.

The hot cutting/welding works with most synthetic fabrics that we use for MYOG.

The welding is very helpful when preparing Noseeum netting vents and windows for backpacking tents. The pesky stretch of the netting can be controlled by hot cutting/welding that is followed by easy sewing to form a narrow frame of straight grain fabric.

For my full ramble on all the many hot knife cutter welder tricks please my full post:

https://timtinker.com/hot-knife-cutter-and-more/

Tim